More and more architects are designing structures that incorporate curved steel profiles, whether they are angle steel, bars, beams, channels, tees, pipes, or tubes. The increased use of curved steel results from the continuous enhancement of manufacturers’ bending capabilities and the desire of owners, architects, and engineers to build exceptionally beautiful and efficient structures.

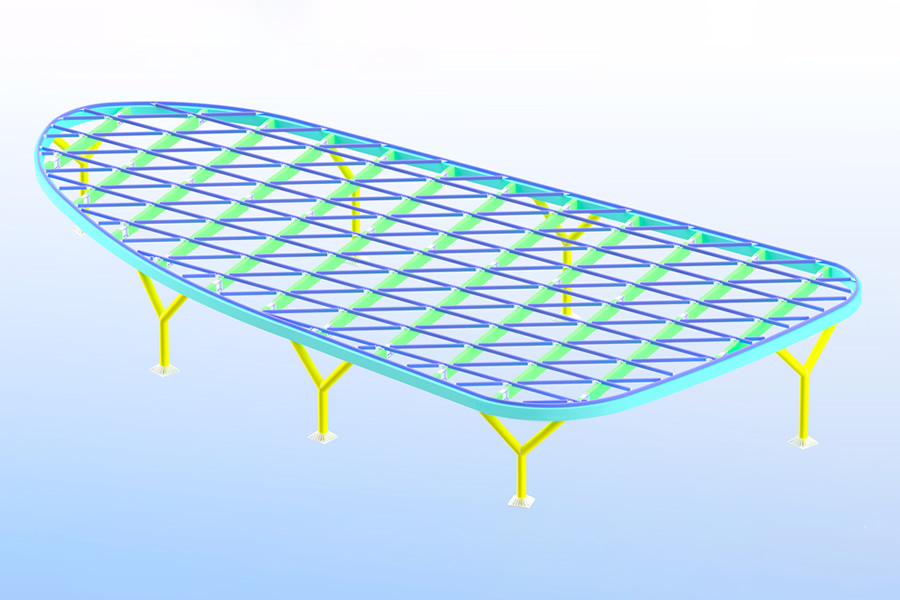

CHEC GOLD Engineering’s design team utilizes BIM three-dimensional design technology, replacing traditional two-dimensional design methods, to create extraordinary forms for curved steel structures. The design team engages in parametric collaborative design, establishing a unified collaborative design model framework and unfolding the entire project, creating a “design skeleton.” The major components are further broken down based on the framework, progressively designing each part.

Components before unfolding can be conditionally associated through assembly, allowing parts to be independently designed after unfolding, achieving collaborative design objectives. Alternatively, component design can be done separately, with assembly taking place later. This enhances engineering efficiency.

Parametric design is another fundamental feature of three-dimensional design software, distinguishing it from traditional two-dimensional design methods. One of the outstanding advantages of parametric design is that it allows easy self-adjustment during design modifications.