High-pressure gas-specific equipment and high-pressure gas containers, collectively referred to as pressure vessels, are commonly used in industries such as chemical and oil refining. The safety of pressure vessels involves various aspects, including design, manufacturing, installation, inspection, use, and maintenance, with design being the most critical factor, as it determines whether pressure pipelines can operate safely.

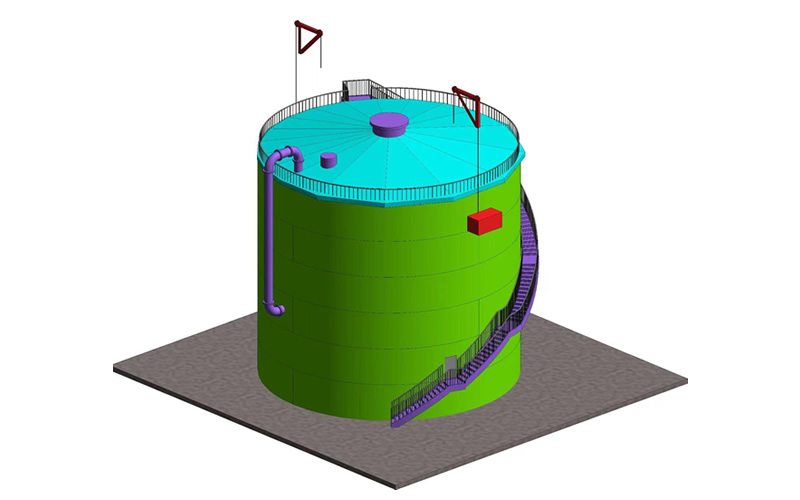

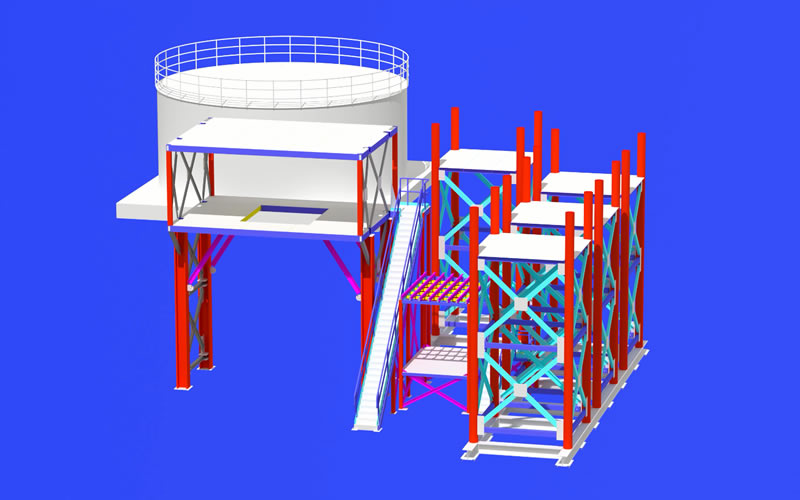

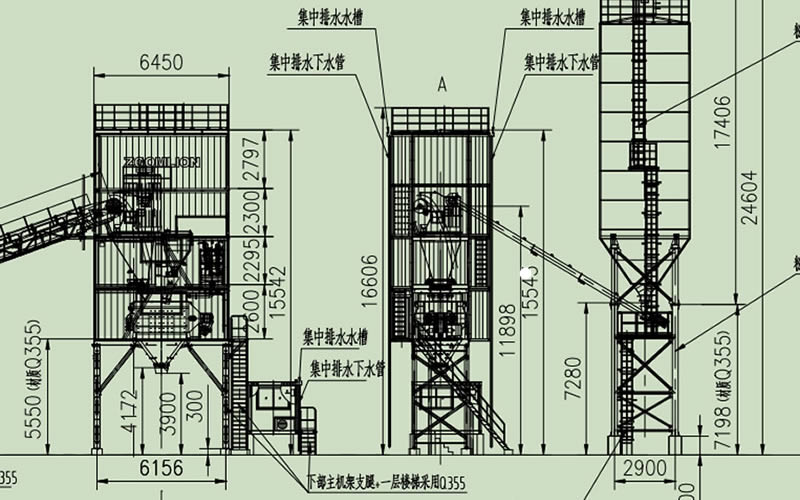

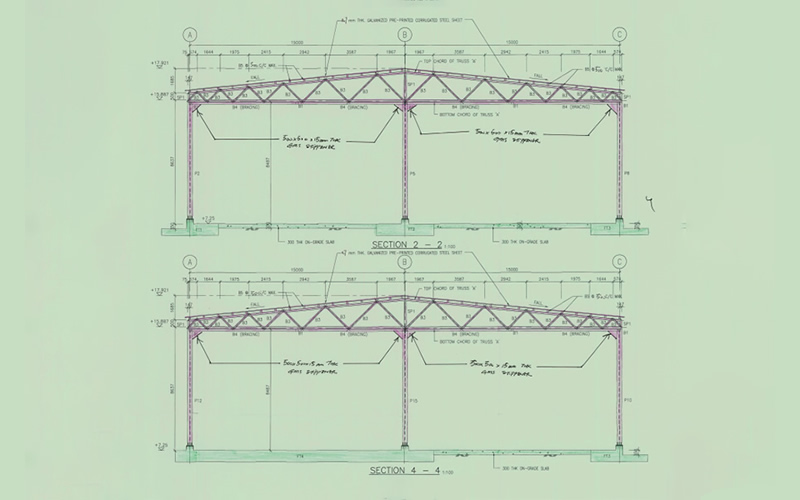

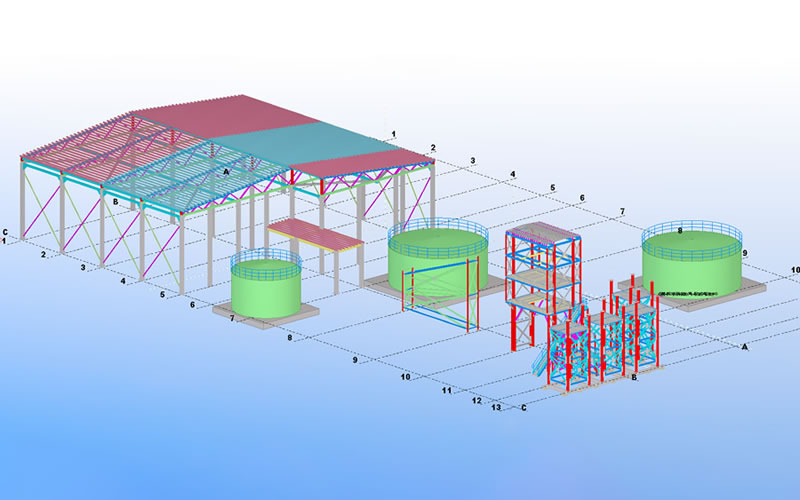

CHEC GOLD Engineering has an experienced design and construction team with rich experience in the design and installation of storage and pressure vessels (cylinders and hydraulic cylinders). We customize solutions based on specific on-site requirements.

Pressure Vessel

Pressure vessels typically consist of six main components: the cylinder body, heads, flanges, sealing elements, openings and connections, supports, as well as safety devices, gauges, and internal parts with different production processes for various functions.

The selection of pressure vessel materials and strength calculation are the primary considerations in the safety design of pressure vessels. The higher the strength of the steel, the lower its toughness will be and it will become brittle. The final selection of materials should be discussed from various factors such as usage environment, operating stress, operating conditions, maintenance status, gas type, temperature, pressure and impurity content.

Because they are often used in harsh environmental conditions such as high temperatures and high pressures, pressure vessels often suffer from fatigue, aging, stress corrosion, corrosion, thinning, and deterioration of welded parts under the influence of long-term loads and environmental stresses, resulting in adverse effects on the safety of the overall structure. produce considerable adverse effects. In order to ensure the safety and usability of the pressure vessel structure, it is necessary to conduct safety inspections and remaining life assessments of the pressure vessels, and implement regular inspections of the pressure vessels.

If you are looking for competitive pricing and the highest quality contractors for pressure vessels and pressure piping engineering in Hong Kong, please send your detailed requests to:contact@checgold.com , We are ready to address any questions related to your project.

Pressure Piping

Pressure piping is a special equipment used for the transportation of gases or liquids using a certain level of pressure. Yamgold Engineering is qualified for pressure piping design and construction, and we tailor solutions to specific on-site requirements.

Features of Pressure Piping

- Pressure piping has a high length-to-diameter ratio, making it prone to instability. It is subject to more complex stresses than pressure vessels. The flow of fluids in pressure piping is complex, with limited buffering, and the operational conditions change frequently, including high temperatures, high pressures, low temperatures, low pressures, displacement deformations, wind, snow, earthquakes, and more.

- Various types of components and supports are used in pressure piping, each with specific material characteristics and technical requirements. Material selection is complex.

- Pressure piping has more potential leakage points than pressure vessels.

If you are looking for competitive pricing and the highest quality contractors for pressure vessels and pressure piping engineering in Hong Kong, please send your detailed requests to:contact@checgold.com , We are ready to address any questions related to your project.